|

Welcome to the Advanced Manufacturing Laboratory

Here

we focus on the scientific investigation of

advanced manufacturing processes to improve

quality and productivity in industry, as well as

advanced robotic techniques for industrial and

health care applications. Much of our work

accomplishes this via laser technologies.

Recent Publications

Laser Forming of

Sandwich Panels with Metal Foam Cores,

(2018)T. Bucher, S. Cardenas, R. Werma, W.

Li, Y.L. Yao.

Laser forming

allows bending metal foam sandwich panels up

to large angles without reducing the

shock-absorption capacity of the foam core

or delaminating the metallic facesheets.

This technology opens up many potential

applications in the aerospace, automotive,

and energy industries.

Interlaminar Toughening of

Fiber-Reinforced Polymers by Synergistic

Modification of Resin and Fiber,

(2019).

Bian,

D., Tsui, J.C., Kydd, R.R., Shim, D.J., Jones,

M., Yao, Y.L.

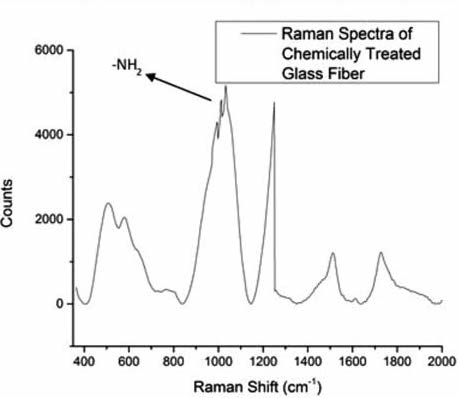

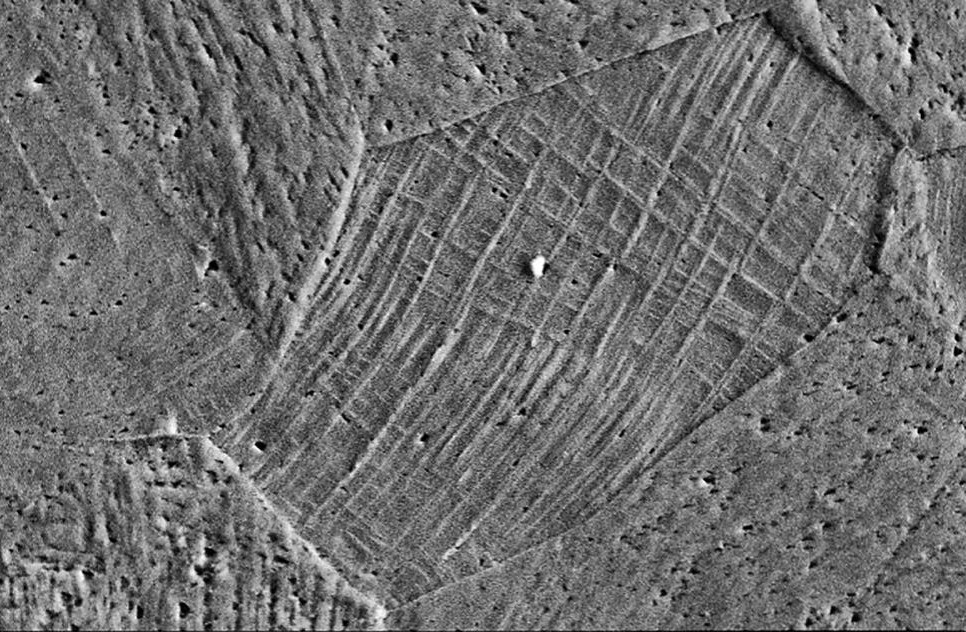

The synergistic effect of combining different

modification

methods was investigated in this study to

improve the interlaminar toughness and

delamination resistance of fiber

reinforced polymers (FRP). Epoxy-compatible

polysulfone (PSU) was end-capped with epoxide

group through functionalization, and the fiber

surface was chemically grafted with an amino

functional group to form a micron-size rough

surface. Consequently, the long chain of PSU

entangles into cross-linked thermoset epoxy

network, additionally, epoxide group on PSU

further improves the bonding through chemical

connection to the epoxy network and amino group

on the fiber

surface. The feasibility of using this method in

vacuum-assisted resin transfer molding was

determined by rheometry. The chemical modifications

were characterized by Raman spectroscopy to

determine the chemical structures. Synergistic

effect of the modification

was established by mode I and mode II fracture

tests, which quantify the improvement on

composites delamination resistance and

toughness.

Laser

Shock Peening for Suppression of

Hydrogen-Induced Martensitic Transformation

in Stress Corrosion Cracking

(2017). G. Brandal, Y.L.Yao

Laser shock peening (LSP) improves the

resistance of a material to stress corrosion

cracking. The increased resistance is not

just attributed to compressive residual

stresses, but is also due to microstructural

changes that occur during LSP. Dislocations

created during LSP reduce the hydrogen

concentration, thereby preventing the phase

transformation from austenite to martensite.

|

|

Recent News

AML welcomed two new PhD

students in Fall 2019. Veronica Over

is no stranger. She received her BS and is

completing her MS degree, both in Mechanical

Engineering at Columbia University. In the

past summer, She interned at the premiere

semiconductor equipment manufacturer, ASML

in CT. Estefania Bohorquez joined us

from University of Central Florida, where

she received a BS in Civil Engineering. She

had research experience in Germany and MIT

Lincoln Lab and is a recipient of the NSF

Graduate Research Fellowship Program (GRFP).

A warm welcome to both again!

Prof. Yao attended MSEC/NAMRC

Conference in Erie, PA June 10-13,

2019. He presented a paper “3D Laser

Forming of Metal Foam Sandwich Panels,”

which is based on a collaboration with

Boeing Company and funded by a GOALI grant

from National Science Foundation. He also

hosted an editorial board meeting of ASME

Journal of Manufacturing Science and

Engineering, of which he is the editor.

Tanzim Azad and Conner

Evans started

their 8-week summer research with AML June

3, 2019. They were supported by Research

Experience for Undergraduates (REU) program

of National Science Foundation. Each of

them is involved in an active research

project going on in the AML.

Tom Zhang successfully

passed his doctoral qualifying exam May

2019. Congratulations, Tom!

Dr. Grant Grandal, a recent

alumni of AML, received the prestigious

Outstanding Young Manufacturing Engineer

Award from SME

https://www.sme.org/2018-outstanding-young-manufacturing-engineers/

during the 46th North American Manufacturing

Research Conference held June 18-22, 2018 at

Texas A&M University. The award was

conferred partially based on his work at GE

Global Research since he graduated from AML.

The award is to recognize accomplished

individuals at age of 35 or younger.

More

|